| Items |

EAG LB-60 (TruBlu)

60 Kilowatt (kW) Electric Portable Dry Steam Cleaner with TruBlu

List Price QUOTE

|

EAG LG-10 (TruBlu)

10 Kilowatt (kW) Electric Portable Dry Steam Cleaner with TruBlu

List Price QUOTE

|

EAG LG-20 (TruBlu)

20 Kilowatt (kW) Electric Portable Dry Steam Cleaner with TruBlu

List Price QUOTE

|

EAG LG-30 (TruBlu)

30 Kilowatt (kW) Electric Portable Dry Steam Cleaner with TruBlu

List Price QUOTE

|

EAG LG-40 (TruBlu)

40 Kilowatt (kW) Electric Portable Dry Steam Cleaner with TruBlu

List Price QUOTE

|

|

Description

|

N/A

Standard Features: - With the exception of our hawk series, all of our steam generators are built by an ASME Certificate holder in accordance with ASME BPVC Section I – Rules for Construction of Power Boilers (“ASME BPVC Section I”). They also comply with the requirements outlined in The National Board Synopsis of Boiler and Pressure Vessel Laws, Rules and Regulations (NB-370) RULES FOR CONSTRUCTION AND STAMPING section, which for many jurisdictions include but are not limited to ASME BPVC Section I, ASME CSD-1, ASME B31.1, and REGISTRATION WITH THE NATIONAL BOARD.

- Dual Pressure Controls (UL 353)

- Low Level Cut-Off (LLCO) (UL 353)

- Safety Relief Valve possessing the ASME V Mark (these valves are built by a manufacturer holding a valid ASME Certificate of Authorization)

Included Options (Standard for Eagle Series Generators): - Steam Gun (33 ft Hose)

- Steam Tool Accessories Kit

Click here to read the NB-370 synopsis.

|

|

Brands

|

N/A

Electro-Steam™

|

|

Electrical Power

|

N/A

60 kW

|

N/A

10 kW

|

N/A

20 kW

|

N/A

30 kW

|

N/A

40 kW

|

|

Boiler Horse Power

|

N/A

6.0 bhp

|

N/A

1 bhp

|

N/A

2 bhp

|

N/A

3.0 bhp

|

N/A

4.0 bhp

|

|

Alternating Current (AC) Power Supply Voltage1

|

N/A

440 V480 V600 V

|

N/A

208 V230 V380 V415 V440 V480 V600 V

|

N/A

208 V230 V380 V415 V440 V480 V600 V

|

N/A

208 V230 V380 V415 V440 V480 V600 V

|

N/A

380 V415 V440 V480 V600 V

|

|

Phase

|

N/A

3

|

|

Frequency

|

N/A

50 Hz60 Hz

|

|

Approximate Heat Up Time

|

N/A

15 min

|

N/A

25 min

|

N/A

15 min

|

N/A

10 min

|

N/A

7 min

|

|

Steam Capacity2

|

N/A

207.0 lb/hr93.9 kg/hr

|

N/A

34.5 lb/hr15.7 kg/hr

|

N/A

69.00 lb/hr31.30 kg/hr

|

N/A

103.5 lb/hr47.0 kg/hr

|

N/A

138.0 lb/hr62.6 kg/hr

|

|

Water Consumption

|

N/A

24.8 gal/hr93.9 L/hr

|

N/A

4.13 gal/hr15.7 L/hr

|

N/A

8.27 gal/hr31.30 L/hr

|

N/A

12.4 gal/hr47.0 L/hr

|

N/A

16.5 gal/hr62.6 L/hr

|

|

Gross British Thermal Units (BTU) Output

|

N/A

200,852 Btu/hr

|

N/A

33,475 Btu/hr

|

N/A

66,951 Btu/hr

|

N/A

100,426 Btu/hr

|

N/A

133,901 Btu/hr

|

|

Maximum Boiler Pressure

|

N/A

200 psi

|

|

Operating Pressure Range

|

N/A

5 to 160 psi

|

|

Operating Pressure (Factory Set Point)

|

N/A

160 psi

|

|

Boiler Temperature

|

N/A

212 to 371 ºF

|

|

Temperature at Tip

|

N/A

212 to 250 ºF

|

|

Maximum Boiler Capacity

|

N/A

15 gal

|

N/A

6 gal

|

N/A

6 gal

|

N/A

6 gal

|

N/A

6 gal

|

|

Boiler Fill Capacity

|

N/A

11 gal

|

N/A

4.2 gal

|

N/A

4.2 gal

|

N/A

4.2 gal

|

N/A

4.2 gal

|

|

Reservoir Tank Capacity

|

N/A

28 gal

|

N/A

7 gal

|

N/A

7 gal

|

N/A

7 gal

|

N/A

7 gal

|

|

Boiler Material 3

|

N/A

Carbon Steel

|

|

Cabinet Material

|

N/A

304 Stainless Steel

|

|

Plumbing Material

|

N/A

Brass (Schedule 80) Carbon Steel (Schedule 80)

|

|

Crated Weight

|

N/A

1,250 lb

|

N/A

725 lb

|

N/A

725 lb

|

N/A

725 lb

|

N/A

725 lb

|

|

Amperage at 208 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

|

N/A

38.6 A

|

N/A

66.3 A

|

N/A

94.1 A

|

N/A

|

|

Amperage at 240 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

|

N/A

38.7 A

|

N/A

64.9 A

|

N/A

91.1 A

|

N/A

|

|

Amperage at 380 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

|

N/A

21.8 A

|

N/A

37.0 A

|

N/A

52.2 A

|

N/A

67.4 A

|

|

Amperage at 415 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

|

N/A

21.1 A

|

N/A

35.1 A

|

N/A

49.0 A

|

N/A

62.9 A

|

|

Amperage at 440 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

95.3 A

|

N/A

18.9 A

|

N/A

32.0 A

|

N/A

45.1 A

|

N/A

58.2 A

|

|

Amperage at 480 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

90.2 A

|

N/A

18.3 A

|

N/A

30.3 A

|

N/A

42.3 A

|

N/A

54.4 A

|

|

Amperage at 600 Volt (V) Alternating Current (AC) Voltage (3Ø Phase)

|

N/A

73.5 A

|

N/A

15.1 A

|

N/A

24.7 A

|

N/A

34.3 A

|

N/A

43.9 A

|

|

Length

|

N/A

75 in

|

N/A

58 in

|

N/A

58 in

|

N/A

58 in

|

N/A

58 in

|

|

Width

|

N/A

27 in

|

N/A

23 in

|

N/A

23 in

|

N/A

23 in

|

N/A

23 in

|

|

Height

|

N/A

69 in

|

N/A

57 in

|

N/A

57 in

|

N/A

57 in

|

N/A

57 in

|

|

Cleaning Method

|

N/A

Dry Steam

|

|

EAG00001 Steam Gun Complete with 33 Feet (ft) Hose (Qty:1)

|

N/A

|

|

EAG00005 8 Inch (in) Curved Lance (Qty:1)

|

N/A

EAG00005 8 Inch (in) Curved Lance (Qty:1)

|

|

EAG00006 16 Inch (in) Curved Lance (Qty:1)

|

N/A

|

|

EAG00007 35 Inch (in) Curved Lance (Qty:1)

|

N/A

EAG00007 35 Inch (in) Curved Lance (Qty:1)

|

|

EAG00008 1 Inch (in) Circular Nylon Brush (Qty:6)

|

N/A

EAG00008 1 Inch (in) Circular Nylon Brush (Qty:6)

|

|

EAG00009 1 Inch (in) Circular Bronze Brush (Qty:6)

|

N/A

EAG00009 1 Inch (in) Circular Bronze Brush (Qty:6)

|

|

EAG00010 1 Inch (in) Circular Stainless Steel Brush (Qty:6)

|

N/A

EAG00010 1 Inch (in) Circular Stainless Steel Brush (Qty:6)

|

|

EAG00011 2.5 Inch (in) Circular Nylon Brush (Qty:6)

|

N/A

EAG00011 2.5 Inch (in) Circular Nylon Brush (Qty:6)

|

|

EAG00012 2.5 Inch (in) Circular Bronze Brush (Qty:6)

|

N/A

EAG00012 2.5 Inch (in) Circular Bronze Brush (Qty:6)

|

|

EAG00013 2.5 Inch (in) Circular Stainless Steel Brush (Qty:6)

|

N/A

EAG00013 2.5 Inch (in) Circular Stainless Steel Brush (Qty:6)

|

|

EAG00014 2.5 Inch (in) Circular Scrubbing Pad Holder (Qty:3)

|

N/A

|

|

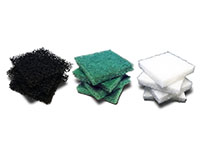

EAG00015 Scrubbing Pads (Qty:12): Black - Heavy Duty (Qty:4)/Green - Medium Duty (Qty:4)/White - Light Duty (Qty:4)

|

N/A

|

|

EAG00038 Heat Resistant Gloves (Qty:1)

|

N/A

|

|

EAG00039 Safety Glasses (Qty:1)

|

N/A

|

|

EAG00055 O-Rings for Steam Gun Connector (Qty:25)

|

N/A

|

|

EAG00067 O-Rings for Steam Gun Tip (Qty:25)

|

N/A

|

|

Working Pressure

|

N/A

|

|

TruBlu Steam Temperatures

|

N/A

|

|

TruBlu Temperature at Nozzle Tip

|

N/A

|

|

Available Voltages

|

N/A

|

|

Optional Equipment for Any Unit

|

N/A

|

|

Industry Standards

|

N/A

American Society of Mechanical Engineers (ASME) - CSD-1 Compliant American Society of Mechanical Engineers (ASME) - Miniature Boiler Code American Society of Mechanical Engineers (ASME) Section I - V-Stamp Underwriters Laboratories (UL 353)

|

|

Additional Steam Tools

|

N/A

Click here for Additional Steam Tool and Options

|

|

Additional Description

|

N/A

|